Même – Experimental House

Même – Experimental House

30. November 2012

Located on the 185,000-square-meter site of a former ranch in Taikicho, Hokkaido, Même Meadows is a unique research facility for studying design responses to the region’s harsh climate. The environmental technology research institute based at the Meadows focuses on the collaborative promotion of next-generation residential design, and was founded in October 2011 by LIXIL JS Foundation.

Situated within Même Meadows, Même is an experimental house for cold climates designed by architect Kengo Kuma with technical support from the Tomonari Yashiro Laboratory at the University of Tokyo’s Institute of Industrial Science. The house takes for its motif the traditional homes of Hokkaido, but incorporates advanced concepts from both Kuma and Yashiro, including a geothermal floor heating and heat storage system and a translucent white double skin that covers the walls and ceiling and provides excellent insulation. The experimental house also allows for the long-term monitoring of changes in the thermal environment as well as collection of earthquake-related data.

Japan Architects asked Kengo Kuma about the project.

Living and dining area

Tell us about the basic concept for the project.

Même takes many ideas from a type of traditional Ainu home called a chise. [The Ainu are Hokkaido’s indigenous people.] We call chise "grass houses" because they are covered entirely in kaya [grasses used for thatching] and sasa [bamboo grass], which provide insulation. We also call them "earth houses" because residents lay cattail mats directly on the earth, which they warm by keeping a fire constantly burning in the hearth. The absorption of this radiant heat from the earth is the basic principle of chise. Our design acheives the softness of a grass house through the membrane material used in the walls and ceiling. Soft as a stuffed animal, the structure sits directly on top of the earth. ["Même" is the name of the district where the house is located. It means "the same" in French and "place where springs well up“ in Ainu.]

Looking from the study to the bedroom

Does the actual house differ in any way from your original design? Tell us about any problems you encountered and how you solved them.

In order to keep in heat, traditional chise are dark and closed off. I wondered if it would be possible to create a bright interior by using translucent walls and roofing.

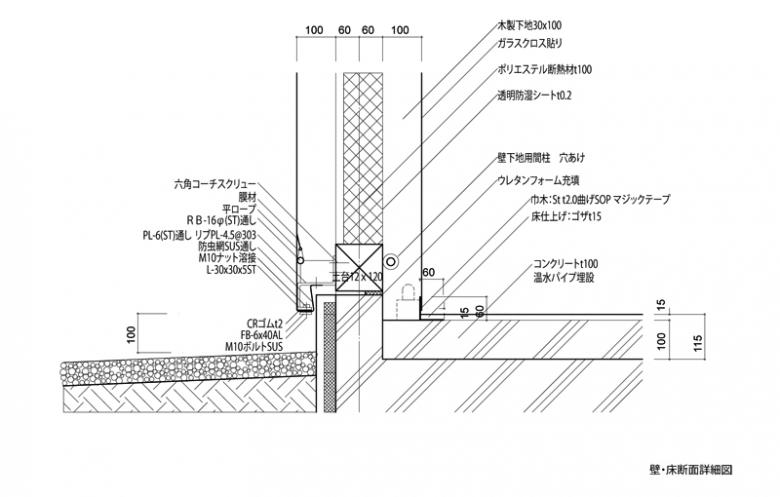

We wrapped a frame built from locally-harvested larch in a membrane coated with polyester fluororesin, then covered the inside of the frame with removable glass fiber cloth. In between the two layers we stuffed transparent polyester insulation made from recycled plastic bottles. The basic concept behind this sectional composition was to create a convection current flowing between the outer and inner membranes that would maintain a comfortable interior environment.

This house made of membranes also open up the possibility of residents synchronizing their daily life with natural rythyms – of not using any artificial lights but instead rising with the sun and going to sleep when it gets dark.

Exterior at night

How is this project different or similar to your past work?

Because this isn’t simply a house, but rather an experimental house, it had to include temperature and humidity sensors, and the windows and finishing materials had to be removeable. For example, the insulated wooden window frames are attached to the exterior of the membrane. It’s a new method that allows for a range of window frames to be tested out while monitoring the living environment inside the house. Along the same lines, the glass fiber cloth inside is attached entirely with Magic Tape [similar to Velcro] to allow for a range of environmental experiments.

Exterior at night

How does this project fit into current architectural trends?

Rather than the static environmental engineering of the twentieth century, which focused exclusively on heat transmission coefficients and attained insulation simply by adjusting the thickness of the insulating material, we were aiming for a more active type of environmental engineering. The use of radiant heat from the floor is one part of that. It’s possible to turn off the floor heating system in winter and live in the house with no heating at all for a period of several days. Instead of closing off the house to keep out the cold, I wanted to design a light environment that felt similar to being outside on an open field bathed in sunlight.

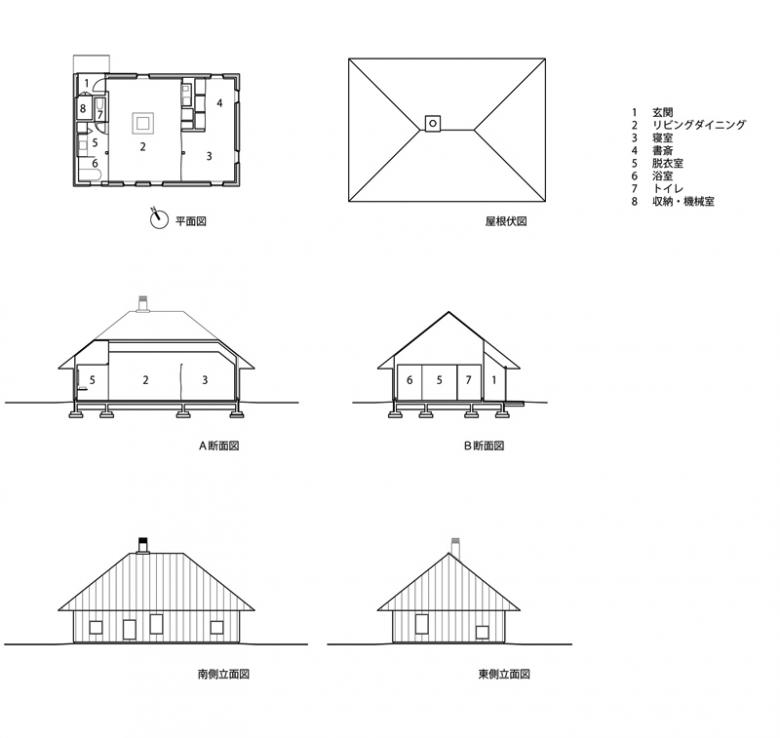

Floor plan, sectional drawing, elevation plan

Sectional detail

Sectional detail

Email Interview by Yuna Yagi

Même – Experimental House

2011

Hokkaido

Client

LXIL JS Foundation

Architects

Kengo Kuma & Associates

Tokyo

Design Principal

Kengo Kuma

Project Architect

Takumi Saikawa

Structural Engineer

Yasushi Moribe (Showa Womden’s University)

MEP/FP Engineer

Bumpei Magori (Factor M / Institute of Industrial Science, the University of Tokyo)

Contractor

Takahashi Construction Co.,Ltd.

Membrane Constractor

Kyoritsu Industries Co., Ltd.

Visualization system for temperature and humidity

Tomonari Yashiro Laboratory, Institute of Industrial Science, the University of Tokyo (collaboration)

Site Area

Approx. 185,000 ㎡

Building Area

79.50 ㎡

Total Floor Area

79.50 ㎡

Photos

Kengo Kuma & Associates