SCB

Tooker House

SCB

22. janeiro 2018

Photo: Bill Timmerman

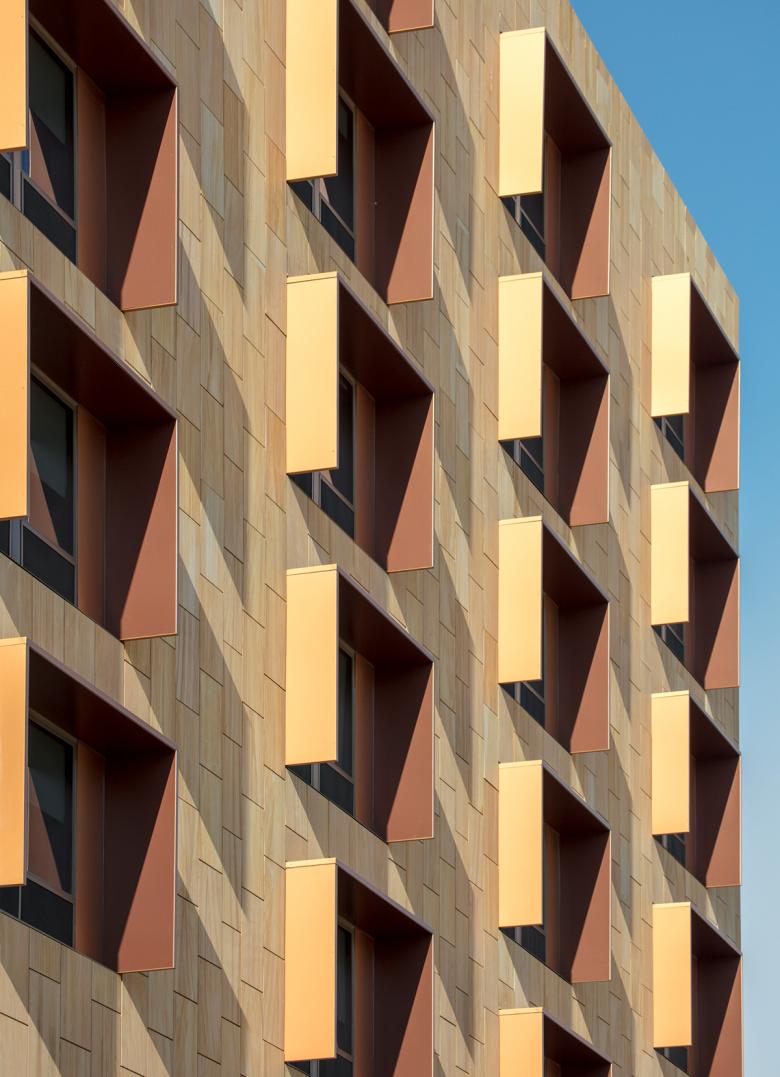

Described as the "dorm built for engineers" on the website of Arizona State University, Tooker House combines student housing and dining with spaces geared to engineering students, such as digital classrooms and a makers lab. Housing nearly 1,600 beds, in rooms shaded from the hot desert sun, the sizable project is broken down into smaller volumes connected by bridges. SCB answered a few questions about Tooker House.

Project: Tooker House, 2017

Location: Tempe, Arizona, USA

Client: Arizona State University, American Campus Communities

Architect: SCB, Chicago/San Francisco

Design Principal: Jim Curtin, AIA

Project Architect: Michael Thompson, AIA, LEED AP

Project Manager: Chadd Harrison, LEED AP BD+C

Structural Engineer: PK Associates

MEP/FP Engineer: GLHN

Landscape Architect: Trueform

Contractor: Okland Construction

Glass: Viracon

Cooper Wall Panels: Kingspan

Stone Facade: Sandstone rainscreen on Kingpspan KarrierPanel

Building Area: 458,000 sf

Photo: Bill Timmerman

What were the circumstances of receiving the commission for this project?

Tooker House was developed by American Campus Communities and delivered through a Public Private Partnership (P3) model with Arizona State University.

Photo: Bill Timmerman

Please provide an overview of the project.

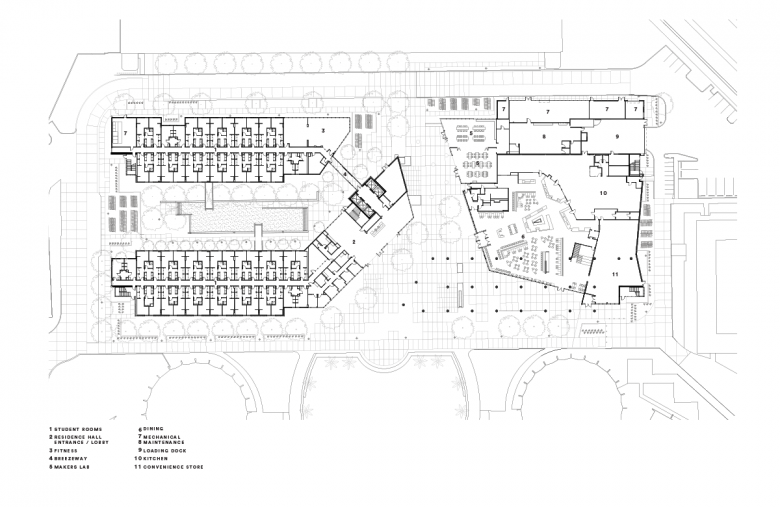

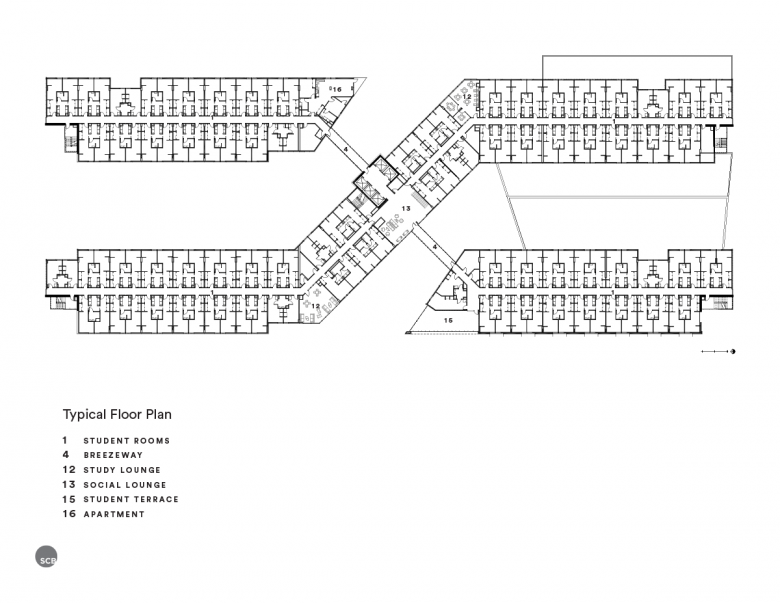

Tooker House at Arizona State University is a new seven-story, 458,000-square-foot living/learning facility for freshman engineering students. The building features 1,582 beds of student housing; five staff apartments; a 27,000-square-foot, 525-seat dining hall; a convenience store; numerous dedicated student study and social lounges; and a large maker lab and flexible classroom.

Photo: Bill Timmerman

What are the main ideas and inspirations influencing the design of the building?

Using the vernacular of desert architecture as its point of departure, the design team sought to create a sustainable building appropriate to its context that could endure, and even leverage, the harsh desert climate of Tempe. The siting, massing, and form of the building were all informed and developed through extensive site and climate studies.

The design was also very much influenced by the intended residents and users of the building. As the new home for engineering students, the design team sought to honestly express the engineering and sustainable design elements of the complex in as many forms as possible throughout the project’s spaces to support a strong living/learning community. For example, the project’s mechanical room is located prominently on the ground level and is glazed to reveal mechanical systems for the benefit of residents. The function of each piece of equipment is denoted with varying vibrant colors and graphic signage to pique residents’ interest and invite learning. Rainwater harvesting is expressed visually in the interior courtyard, offering unique visual design interest and also facilitating residents’ understanding of the building’s inner workings and sustainability mission. Meanwhile, the Tooker House Maker Lab enjoys a prominent and highly visible location on the ground floor of the building, allowing students to expand class projects and explore experimental ideas at any time of day or night without having to leave the comfort of their own residence hall. The Maker Lab features sliding glass walls that allow activities to spill outdoors, where exhibition pedestals enable student residents to present their work.

Photo: Bill Timmerman

How does the design respond to the unique qualities of the site?

The building’s siting, shape, and massing were developed through extensive shading studies on the constrained campus site. The complex’s figure-eight shape positions the two primary building masses in parallel positions facing east-west, which allows the building to “self-shade” interior courtyards and facades. The southern façade incorporates U-shaped visors and an array of perforated vertical louvers designed and positioned according to a sophisticated algorithm, presenting visual interest and ensuring appropriate daylight control unique to each window’s location on the façade. The massing also facilitates wind movement, which flows predominantly from a westerly direction, through the interior, shaded courtyards and between the building’s masses. Perforated metal panels on the building’s bridges and breezeways promote airflow through those spaces. Rain water is harvested from the roof and nourishes select landscape zones in bioswales, reducing the reliance on potable water while also reducing the amount of underground piping and vault infrastructure. The building is on target to reach LEED Gold certification.

Photo: Bill Timmerman

How did the project change between the initial design stage and the completion of the building?

This project had a very aggressive timeline. As such, establishing concrete goals that addressed program, design and systems with the university and developer client was critical to not only meeting the schedule, but keeping the project on track aesthetically. The design team knew that within this timeline, there wouldn’t be much room for change. So significant resources were dedicated early in the conceptual design process resources for thorough studies of the site and climate-related influences such as solar radiation and predominant seasonal winds. As the data was compiled, the team found that the interconnectivity of environmental performance and architectural responsiveness would ultimately guide the final design solution. For example, from the solar studies, it was evident that a shading element would be necessary along any southern façade designed for the building. However, given the broad breadth of the building facade, the designers realized that the shading solution was going to play an integral role in controlling the perceived scale and mass of the expansive building. Thus the solution ultimately ended up incorporating two shading approaches: the perforated vertical louvers along the south and southeast facing facades and the opaque solar canopies of the south facing sandstone façade.

Photo: Bill Timmerman

What products or materials have contributed to the success of the completed building?

- Exterior enclosure composed of insulated metal panels and EIFS with an average effective R-value of R:23. These systems provide continuous insulation to reduce thermal bridging.

- Glazing units with significant shading coefficients allow the development and interior spaces to gain transparency and daylight without detriment to thermal performance and comfort.

- Exterior louvers and solar canopies limit solar heat gain on the southern facades.

- Perforated metal cladding on stairs, bridges and terraces provides solar protection while maintaining ventilation in the open-air spaces.

Email interview conducted by John Hill.