Concrete 'Bubbles' Made from Bubble Wrap

John Hill

19. October 2018

Photo: Per Lundström

Two new lecture halls on a medical campus outside Stockholm are covered in concrete panels that glow from the inside, thanks to a technique developed by Sweden's Butong.

Project: NEO - Concrete Bubbles, 2018

Location: Flemingsberg, Stockholm, Sweden

Client: Client: Karolinska Institutet, Veidekke

Architect: Tengbom

Project Team: Krister Bjurström, Anna Morén Sahlin, Kjell Jansson, Anna Mistry Bergbom, Daniel De Sousa Barrera, Miguel Reyes, Sofia Kanje, Kristoffer Adolfsson, Ana Gejo

Computational Design: Shahrokh Kamyab och Jakob Lilliemarck

Manufacturer: Butong

Butong Team: Jean-Charler Violleau, Hamid Yaldan, Malin Wahlström, Staffan Snis, John Nilsson, Lars Höglund, Benjamin Levy

Product: Translucent Concrete Panels

Lighting: Philips (Svante Pettersson, Daniel Ljung, Disco Anders)

Photo: Per Lundström (All images are courtesy of Butong)

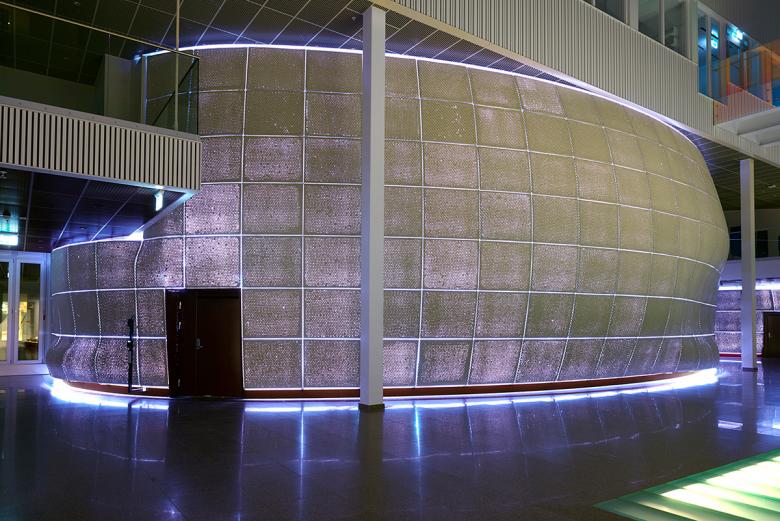

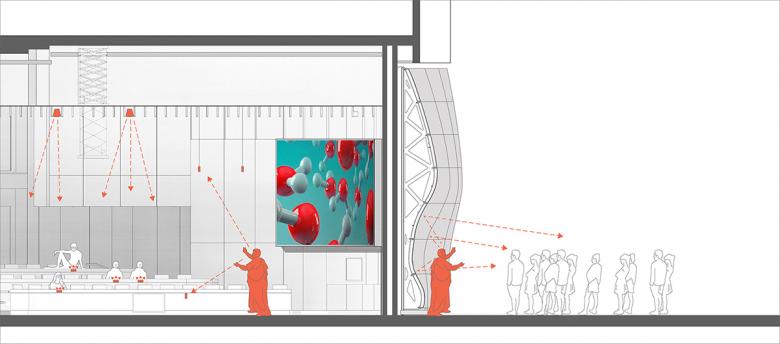

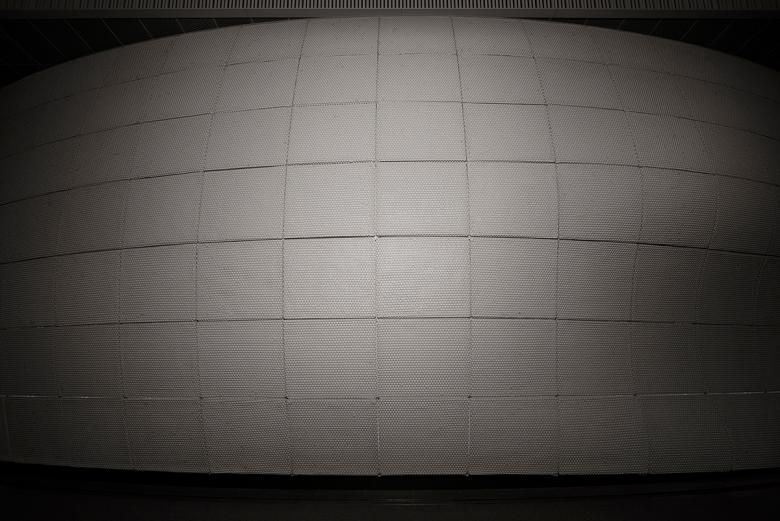

Earlier this year the Karolinska Institutet, a medical university, moved into NEO, the new building on its Flemingsberg campus in suburban Stockholm. KI bills NEO as "a hub for basic and clinical research" and "a living venue for research, aimed to be a creative and open environment that enables meetings, synergies, and exploration of areas of mutual interest across disciplines." Designed by Stockholm's Tengbom, who also designed the neighboring Technology and Health Building, NEO consists of a variety of meeting rooms oriented about a large atrium. It's in this atrium where an oddity can be found: two "Concrete Bubbles" covered with translucent concrete.

Photo: Per Lundström

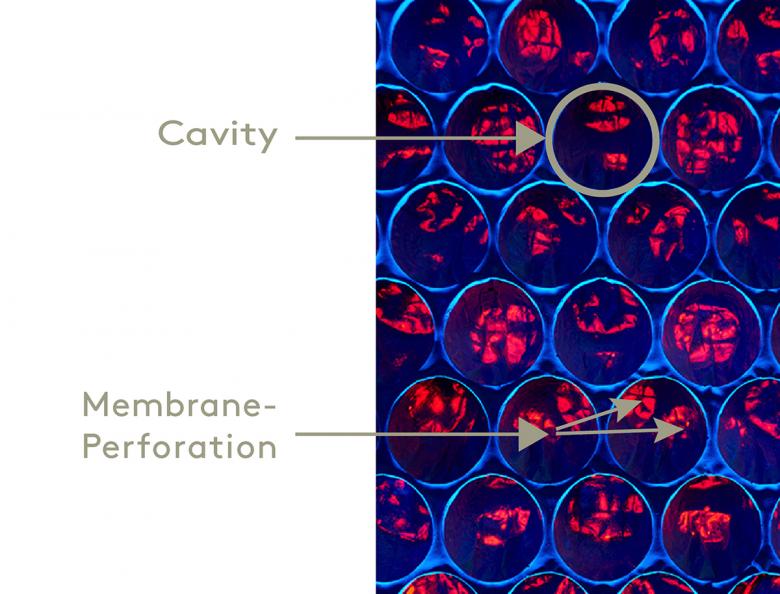

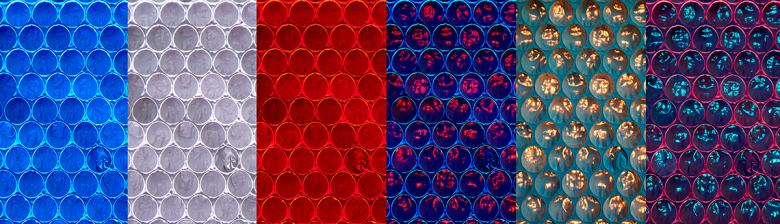

The Concrete Bubbles contain two high-tech lecture halls equipped with large LED screens. Solid panels enclose the lecture halls, so the concrete panels are an outer skin that provides an aeshetic punch. Butong's concrete panels incorporate bubble wrap into their formwork, resulting in a grid of "innies" with small membrane-perforations that allow light to pass. The colors of the concrete panels change according to a light show of LEDs both in front of and behind the panels. The effect may look like light-emitting concrete, but Butong's panels are free of fiber optics and therefore relatively "low-tech." Also, they can be used as armatures for vertical gardens!