A Diamond in the Ceiling

John Hill, Thomas Geuder

16. November 2018

Photo: Gordon Welters

The Staatsoper Unter den Linden (State Opera House) in Berlin traces its origins to 1742, though the building was rebuilt following a fire in the 1840s and bombing in World War II. Although the latest renovation maintains the building's historical architecture, at its heart is an innovative ceramic shell that plays a part in the auditorium's greatly improved acoustics.

Project: Staatsoper Unter den Linden, 2017

Location: Berlin, Germany

Client: Berlin Senate Department for Urban Development and the Environment

Architect: hg merz

Structural Design, Materials and Testing Concept: Knippers Helbig Advanced Engineering

Project Team: Jan Knippers, Matthias Oppe, Florian Scheible, Laurent Giampellegrini

Manufacturer: Fiber-Tech Construction GmbH

Product: Glass fiber reinforced phosphate ceramics (CBPC)

Materials Research: Institute for Building Structures and Design (ITKE), University Stuttgart

Materials Testing: Materials Testing Institute (MPA), University of Stuttgart

The design team decided to raise the ceiling of the original hall four meters - the additional space gained is now used as a reverberation gallery. (Photo: Gordon Welters)

The rehabilitation of the Staatsoper Unter den Linden took eight long years, sometimes accompanied by heated political debates and controversial cultural discussions. In the end, the city has received an opera house whose changes are barely visible despite the complexity of the task that involved, per hg merz, "enhancing the visitor’s comfort, optimizing the visitor guiding system, easing stage operating processes and improving the acoustics." With the building listed, preservation was a strong concern, but so was the auditorium, which dated to the 1950s (it was designed by architect Richard Paulick) and had noticeably poor acoustics. General music director Daniel Barenboim wanted to greatly improve sound in the auditorium, which had a very low, unfavorable spatial resonance and had required the use of an electronic reverberation extension system since the 1990s.

The space gained by the lift was also used for additional equipment, such as lighting. (Photo: Gordon Welters)

Thus Prof. HG Merz, who led the general refurbishment starting in 2009, put a special solution on the table: Without changing the building from the outside or impacting the auditorium's appearance greatly, the ceiling should be raised about four meters. As a result, an additional volume of around 3,000 m³ would be generated, enough to increase the reverberation time from 1.1 seconds to 1.6 seconds. The large cavity, which thereafter has functioned as a reverberation gallery, is defined by a curved surface with a filigree diamond pattern.

The sound-transparent rhomboid structure closes the gap between the upper tier and the hall ceiling caused by the raising of the latter. (Photo: Gordon Welters)

The engineers at Knippers Helbig broke new ground with the production of the diamond pattern, made from glass-fiber-reinforced phosphate ceramics (CBPC). The organic form of approximately 250 square meters was made off site through a casting process. The material meets the project's stringent fire protection requirements, it can be easily integrated into the existing architectural language, and it is also characterized by a high ratio of strength to dead weight. However, similar to concrete, the material's tensile strength is low compared to its compressive strength. Therefore, the phosphate ceramics were reinforced with long and short glass fibers: continuous strands of so-called "textured rovings" laminated into the ceramic mass. Additionally, short fibers were integrated into the surface to ensure a crack-free appearance. Since CBPC's mechanical properties had not been investigated before, research and testing was carried out at the University of Stuttgart's Institute for Building Structures and Design (ITKE) and Materials Testing Institute (MPS).

Rooms such as the Apollosaal at the Staatsoper Unter den Linden were important sources of inspiration for the designers. (Image: Marcus Ebener / Staatsoper Unter den Linden)

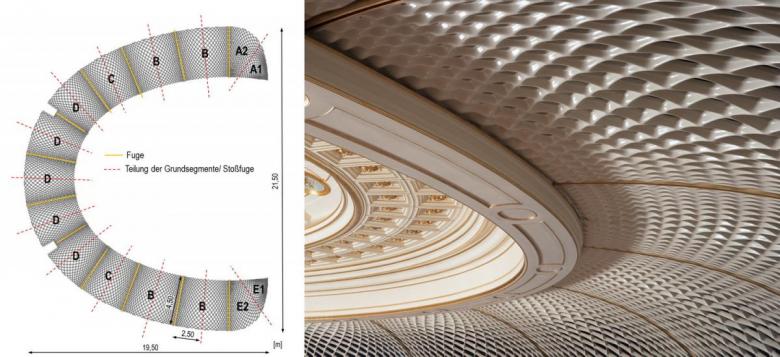

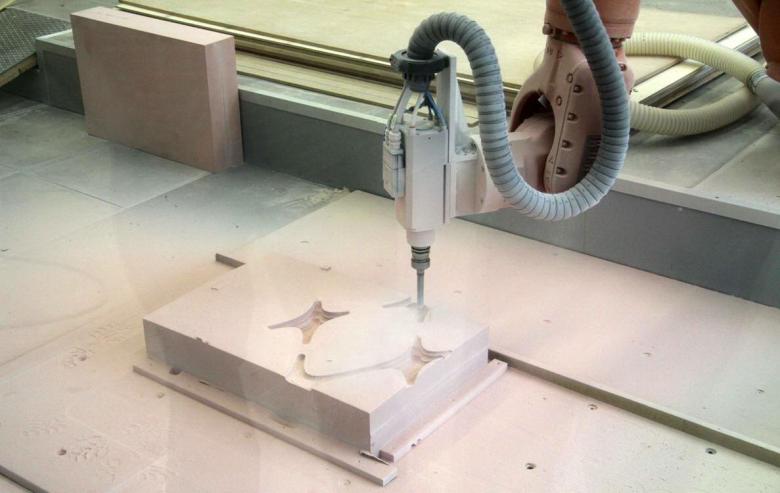

The resulting shell structure consists of thirteen spherically curved elements that are joined with brass profiles. The engineers were able to optimize the individual elements to such an extent that only five different geometries were needed (A-E in drawing below). The rigid polyurethane foam molds were CNC milled using a five-axis gantry robot, determined by data from the parametrically generated 3D models. The ceramics and fibers were then introduced into the finished molds. All this was implemented by Fiber-Tech Construction from Chemnitz, which developed production processes specifically for this project. All together, the team of hg merz, Knippers Helbig and Fiber-Tech managed to write another chapter in the ever-changing architectural history of the Staatsoper Unter den Linden.

Thirteen two-part segments were needed to provide the reverberation gallery with the rhomboid structure integrated into the historic hall. (Drawing: Knippers Helbig; Photo: Marcus Ebener)

Production involved a five-axis gantry robot that milled the molds in rigid polyurethane foam. (Photo: Knippers Helbig)

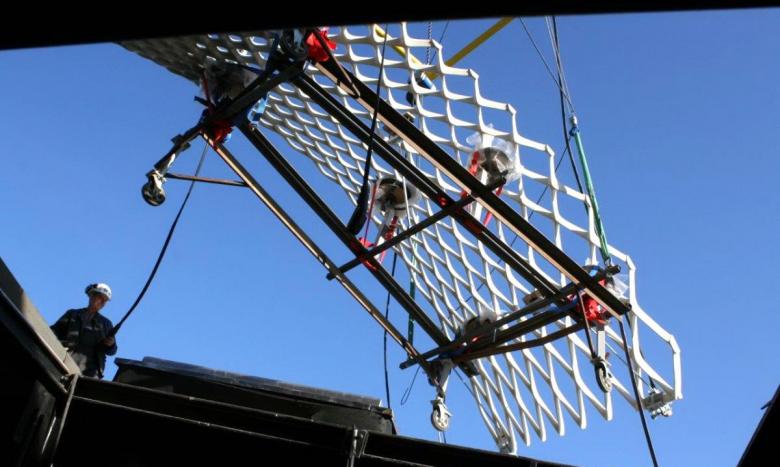

The geometry was optimized to reduce the individual elements to five geometries: A-E. (Photo: Fiber-Tech)

Continuous strands of so-called "textured rovings" were laminated over several layers of ceramics in accordance with the intersecting diamond diagonals. (Photo: Fiber-Tech)

The shell elements were delivered by means of a crane through an opening in the roof. (Image: Fiber-Tech Construcion GmbH)

Since the end of 2017, the Staatsoper Unter den Linden has been a shining presence in the historic heart of Berlin. (Photo: Marcus Ebener)

A version of this article originally appeared as "Nachhal(l)tig" on German-Architects.