Center for Manufacturing Innovation

4. de febrer 2015

Santa Monica, California's Brooks + Scarpa headed south of the border to carry out an industrial building with the firm's signature emphasis on sustainability and bold design. Most striking are the perforated skin and jagged roofline, which filter light and views, bring in plenty of north light, and reference the surrounding natural features. The architects answered a few questions about the project.

Please provide an overview of the project.

Metalsa SA began as a family-owned company, founded by Guillermo Zambrano Gutierrez in 1956 that manufactures chassis and structural body components worldwide for a variety of heavy trucks and pickups in facilities located in the USA, China, Japan and India. Today the company has manufacturing facilities located around the world and boasts several major automotive corporations as their clients, including Ford and Toyota.

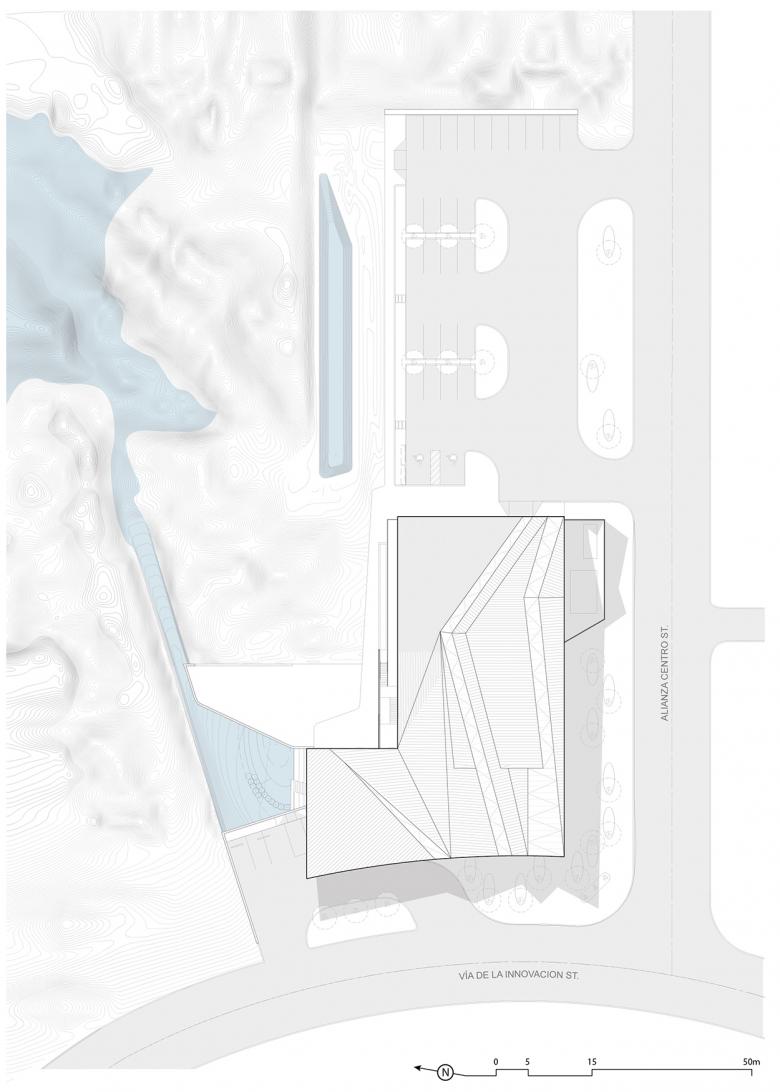

Site: Located in Mexico’s Research Park for Technical Innovation (PIIT), a science and technology park, which is a partnership between government, universities and the private sector to seek economic growth through technical innovation. The 1,000-hectare campus is host to more than 50 research centers devoted to R&D as well as the development of technology innovation in nanotechnology, biotechnology, mechatronics and advanced manufacturing, information technology, clean energy and advanced materials development.

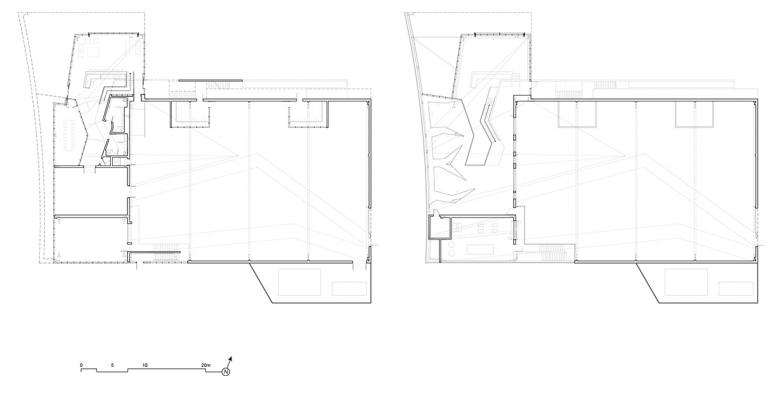

Program: Master planning for a 5,000-square-meter (53,800-sf) research lab, office and industrial testing facility serving an automotive industry client who designs and manufactures automotive and heavy truck chassis. The first phase encompasses a total of 15,500 square feet, including 5,500 square feet of office space and 11,000 square feet of research labs and warehouse space for testing and developing prototypes. The second phase consists of an additional 5,500 square feet of office space and 34,000 square feet of research labs and warehouse space.

Programmatically, the building is divided into two volumes – warehouse/labs and offices functions. The upper story of the offices cantilever over the lower story to the west and is clad in a highly perforated metal skin and is the main entry facade. The lower story is mainly glazed and open to reveal portions of the research laboratory, machine room and other industrial functions not requiring visually security. From the exterior, the warehouse appears to float lightly over the mechanical and intellectual heart of the program, reversing the notion that an industrial building should be solid and protected. Rather, the building seems very open and is intended to feel vulnerable revealing parts of its inner program to public view.

The main entry of the building is located at the northwest corner under the cantilevered volume. It is flanked by a sunken garden to the north, which is overlooked by the surrounding offices. The garden connects to the adjacent water reclamation wetland for the entire PITT campus. A large operable door located off the entry in the main public space opens to the garden outside.

What are the main ideas and inspirations influencing the design of the building?

Industrial buildings of this type are rarely a model for workplace innovation. They are typically a direct, and often nefarious programmatic response to the function inside with little consideration for the occupants needs. The approach to this project was to preserve the integrity of a high bay industrial facility and program, while providing a model environment for the users and visitors.

One major feature of the building is the perforated metal skin that clads the entire façade. The custom aluminum skin is both perforated and etched. It incorporates interplay of solid and void, orchestrating areas of both light and shadow, while limiting views into the research areas, necessary to protect proprietary trade secrets. Thus, the industrial program has been transformed from a black box environment to a light filled space with a strong visual connection to the outside.

How does the building relate to contemporary architectural trends, be it sustainability, technology, etc.?

The building and site are part of the overall ecosystem and are rooted with a strong sense of place. The building is formed around the forces and natural resources of the climate and the site. The building responds not only to sun and wind but also to the natural lay of the land and the context of the existing campus. The landscape design paid particular attention to natural stormwater management techniques, open space preservation, permeable paving systems, and native landscape integration. The integration of the landscaping has already proven to be an exemplary gathering place for people and creates a natural, beautiful and comfortable exterior space to enjoy while strongly contributing to the overall campus master plan.

How did you approach designing for Monterrey/Mexico and how would you describe the process of working on the project there?

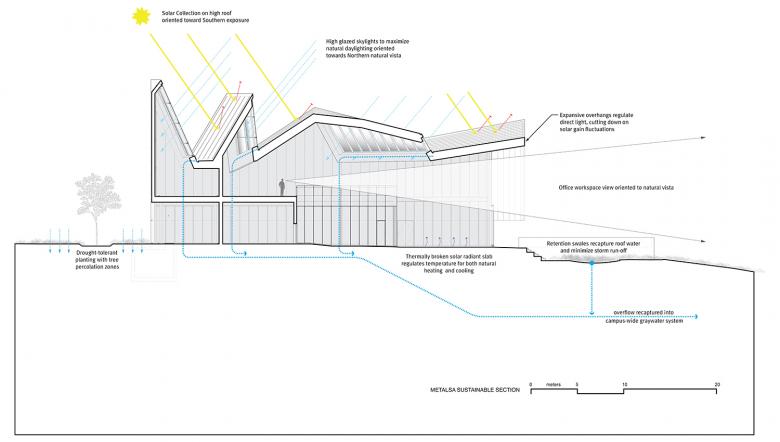

The Building was designed to passively adapt to the temperate climate of Monterrey, Mexico and utilizes strategies that leverage light and air to increase energy performance and improve workplace performance. Large exterior overhangs with metal screens function as light filters and shading devices. Like many of the features at this project all design elements are multivalent and rich with meaning – performing several roles for functional, formal and experiential effect. 100% of the total regularly occupied building area is day lit.

One of the team's primary objectives was to enhance the quality of the research environment for each employee by surpassing standards found in conventional projects. Daylighting all spaces was another primary strategy because it significantly impacts worker productivity, lighting and cooling energy. All rooms have minimum 14-foot-high ceilings. Indoor air quality was emphasized by minimizing off-gassing. Formaldehyde-free FSC certified cabinetry, low-VOC paints, natural stone, and fluorescent lighting with low mercury content were used to minimize pollution from materials.

How would you describe the architecture of Monterrey/Mexico and how does the building relate to it?

A saw-toothed roof draws from the geometry of old factories and the surrounding Monterrey Mountains. The angled elements of the roof provide abundant natural daylight to the spaces below at the building’s northernmost elevations. By modulating space and light through a fractured roof geometry, the building is able to maintain a rational plan to meet the rigorous requirements of the program, while providing a strong connection to the landscape both visually and metaphorically.

Email interview conducted by John Hill.

Site Plan

Floor Plans

Sustainability Section

Center for Manufacturing Innovation

2012

Monterrey, Mexico

Client

Private Auto Components Manufacturer

Architect

Brooks + Scarpa Architects

Santa Monica, California

Design Principal

Lawrence Brooks, FAIA

Design Team

Silke Clemens, Daniel Poei, Abby Katcher, Oliver Liao, Darien Williams, Jordon Gearhart, Ching Luk, Angela Brooks

Architect of Record

Homero Fuentes, Centro de Diseño

Structural Engineer

Carl W. Howe Partners, Inc.

MEP/FP Engineer

Integral Group

Landscape Architect

PEG Office

Sustainability

John Zinner, Zinner Consultants

Engineers of Record

SPID Ingenieros (Structural and Civil); SENSA (Mechanical); DINELEC (Electrical)

Construction Manager

Alex Ruiz Cruz

Site Area

100,000 sf

Building Area

55,000 sf

Photographs

John Edward Linden

Drawings

Brooks + Scarpa